Mining operations

Specializing in “soup to nuts” projects from exploration through reclamation and closure.

OUR APPROACH

Develop practical and efficient mining operation designs and plans that will ensure maximum yield from your reserves, resulting in successful and profitable operations.

Many members of our mining team have years of hands-on experience in the mining industry, prior to providing engineering and consulting services.

Due to our solid reputation among State and Federal agencies, EARTHRES has the skill and experience to be successful in permitting operations in sensitive community environments. Easing the burden on our clients, we are equipped to provide expert testimony and litigation support should the need arise.

We utilize the latest technologies in multimodal surveying, GIS mapping, AggFlow, Surpac, and our years of experience designing and optimizing mining operations.

EARTHRES’ licensed professional engineers, geologists, and environmental scientists will develop practical and efficient mining operation designs and plans that will ensure maximum yield from your reserves, resulting in successful and profitable operations.

CASE STUDY

Combining Bathymetric

and Ground Surveys

The Challenge

A mining client (company confidential) needed reserve estimates and permitted depth data to verify tonnage calculations, dredge operation, and permit compliance. EARTHRES was selected to perform the survey after careful consideration of expertise and the ability to perform underwater and above ground surveys. Requiring both bathymetric and ground survey to multiple locations at a single site, this project was complex and diverse, requiring a company well versed in performing underwater and above ground surveys.

OUR EXPERTISE

Our industry experience sets EARTHRES apart from our competition and allows us to better help you operate and manage a profitable operation.

As a leading engineering consulting company in the industry, our extensive mining experience includes mine planning, reserves analysis, mining engineering, process plant design, permitting, construction, and reclamation. These services are supplemented by our assessment capabilities of existing operations for yield and efficiency improvements, process monitoring, and expert litigation services.

SERVICES INCLUDE ⸺

Government. Regulations. Compliance.

EARTHRES’ understanding of the regulatory requirements combined with our experience with the regulatory agencies and local governments ensures success in navigating through the intricate mine permitting process, even in sensitive community environments. At EARTHRES, our mining team specializes in mine and quarry permitting projects from exploration and throughout the entire life of your operation, including reclamation and final land development. EARTHRES will provide you with the technical and regulatory expertise necessary to keep you in compliance with Federal, State and Local requirements.

Mine Permitting and Environmental Services

Our mine permitting and environmental services consist of:

- All Federal, State and Local Permitting

- Underground Design, Permitting, and Ventilation

- Wetland Services

- Hydrogeology and Geophysics Evaluations

- Air Quality Permitting for Mines, Quarries, Cement, Lime, Aggregate, Concrete, Asphalt, and Industrial Minerals

Mine Design and Operations Support

Exploration. Design. Longevity of Reserves.

Increase the efficiency and longevity of your mining operation with EARTHRES’ mine design and operations support. With a full service, integrated approach, we will be a strategic business partner, developing your mining operation from exploration to completion and beyond. Our extensive understanding of your industry enables us to find creative and practical solutions to meet the needs of your operation.

Many members of our mining team have extensive hands-on experience in the mining industry prior to providing engineering and consulting services. This industry experience sets EARTHRES apart from our competition and allows us to better help you operate and manage a profitable operation.

The operational experience of our management team is the cornerstone of EARTHRES’ service. Our model is to first understand the needs of our clients, then deliver creative and practical designs. Our licensed professional engineers, professional geologists, and environmental scientists develop practical and efficient mine designs and plans.

Exploration, Planning, Design and Reclamation Services

- Exploration and Evaluation

- Mine Planning and Design

- Rehabilitation and Reclamation

- Raw Material Sources

- Deposit Evaluation/Surpac Modeling

- Surveying Services

- Land Development

- Design/Build

M&A, Strategy and Valuation Services

- Feasibility Studies

- Due Diligence/Mergers and Acquisition

- Marketing

Mineral Processing Engineering Services

- Mineral Processing Engineering

- Process Efficiency Analysis

- Aggregate Process Plant Design

- Lab and Pilot Studies

- Design/Build

- Process Simulation/Aggregate Flow

Mine Permitting and Environmental Services

- Mine Permitting

- Underground Design, Permitting and Ventilation

- NPDES Permits

- Wetland Services

- Hydrogeology and Geophysics

- Air Quality for Cement, Lime, and Aggregate

Operations Support Services

- Mine Management

- Wastewater Treatment

- Operations Optimization

- Database Services

- Highwall and Slope Stability Investigations

- Distribution

- Remote Monitoring and Control

- Process Automation

Operations Focused Mine Planning

Assess. Strategize. Implement.

EARTHRES is a name you can trust in the mining industry. We specialize in mine and quarry operations beginning with exploration and lasting throughout the entire life of your operation, including reclamation. Our licensed professional engineers, professional geologists, and environmental scientists develop practical and efficient mine plans and mine operations support for aggregate, coal, sand & gravel, and industrial minerals.

Strategic, operations focused mine planning is more than answering the question, “Where am I going to mine next year?” Operations-focused mine planning is a forward-looking exercise designed to maximize the value to be realized in the development, extraction, and processing of a mineral resource. It allows the company to optimize its capital investment, reduce operating costs, and create value. Strategic mine planning is a critical part of your company’s path to exceptional performance and ensuring sustainable and profitable operations.

The Benefits of Operations Focused Mine Planning

- Reduce Operating Costs and Improve Productivity

- Optimize the Capital Investment and Plans

- Develop Optional Plan Scenarios

- Set Production Targets

- Plan for the Future

- Manage Issues with Variable Ore Grade

- Extend Utilization of Expensive Infrastructure (i.e., Roads, Ramps, Conveyors, Sumps, Pumps, Pipes, etc.)

- Avoid Slope Failures

- Plan for Future Pumping Requirements

- Plan for reclamation and facilitate post-mining land uses

Strategic Mine Planning

Mining operations are expected to encounter increasing opposition from regulators and the public when extracting existing mineral reserves and while permitting additional reserves. As a result, it is important for mining operations to maximize the recovery of permitted reserves in a cost-effective manner. Effective planning of quarry operations can result in an improved product yield, reduced operating costs, and a more consistent product quality. To achieve these results, a strategic mine plan based upon the geology and quality of the mineral deposit can be developed to maintain process control of product yield and quality and reduce operating costs.

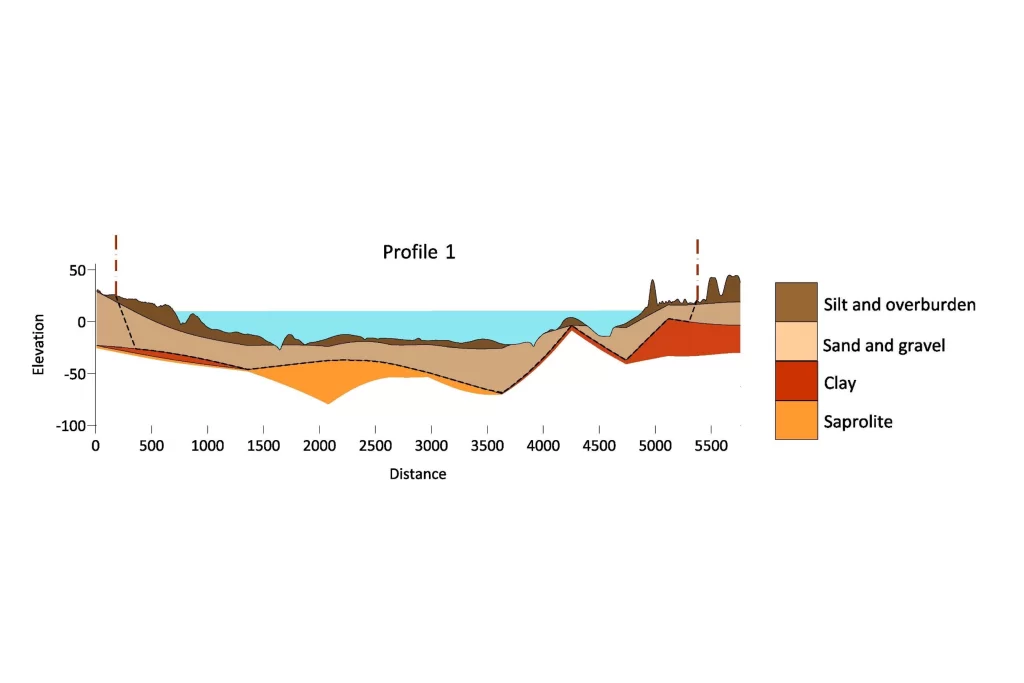

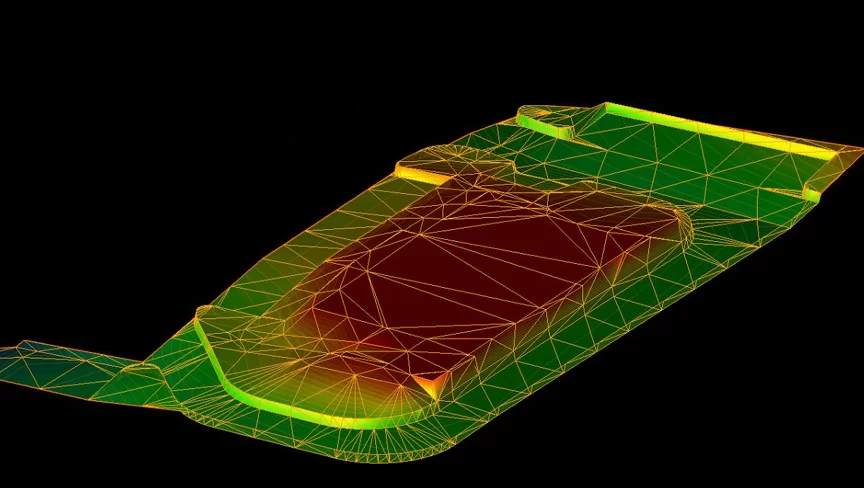

The strategic mine planning method begins with the collection of geologic and quality data from exploration drilling and sampling. This information can be utilized to construct a 3D geologic block model. Following block model creation, a strategic sequence of extraction is developed to meet the targeted criteria or key performance indicators as established by the mine operator. Potential outcomes of strategic mine plan development include a raw mineral blending strategy at the mining operation, potential beneficial reuse of sorted waste streams, or identification of major capital projects in support of active mining operations that are projected to have the largest return on investment.

Other Mining Services:

- Exploration and Reserve Studies/Analysis

- Site Construction Permitting and Land Development

- Mining Engineering, Design and Permitting

- Geotechnical Evaluation and Slope Stability Analysis

- Geology, Hydrogeology and Water Withdrawal Analysis/Permitting

- Mineral Processing Engineering and Design

- Industrial Minerals Consulting

- Process Plant Design

The foundation for both short and long-term success is built on the strategic mine plan. It is the road map to the future.

Mining Engineering

Mining Engineering and Geologic Services

- Mine design and permitting for new mines and expansions

- Exploration and reserves estimation

- Mine planning and operations optimization

- Process plant design

- Hydrogeologic balance assessments and pump tests

- Slope stability and high wall investigations

- Groundwater modeling and zone of influence

- Reclamation and rehabilitation plans

- Beneficial re-use strategies

- Expert testimony and litigation

- Mine surveying using a variety of technologies such as reflectorless total station, 3D scanning, and drones

- Air permitting

- Wetlands delineation

- Mine reclamation fill (clean fill) permitting

Mineral Processing Engineering Services

New Plant Design:

- Evaluate deposit for proper equipment selection

- Design plant to maximize product mix and production

Existing Operation:

- Evaluate and audit plant

- Make recommendations to increase production

- Alternative analyses for improvements

- Understanding of how to create a new higher revenue operating system

- Development of plant upgrade scenarios by modeling different options in Autodesk® AutoCAD® 3D software

3D Surpac Model

3D Surpac Model

- Complete mass balance development

- Field flow measurement: belt cuts, flow meters, density

- Unit analysis and performance evaluation: crushers, screens, cyclones, dryers, classifiers, mills, flotation, calciners, magnets, feeders, and conveyors

- Flowsheet development

- Prioritization of projects based on ROI

- Project management and implementation

Exploration and Feasibility

- Geologic assessment sampling/drilling

- Bench testing

- Analytical and application testing

- Market and economic assessment

Engineering and Construction

- Process flow sheet design and pilot studies

- Detailed engineering and construction oversight

Operations and Marketing

- Plant optimization

- Plant design

- Operator training

- Quality assurance

Minerals Marketing Consulting Services

- Valuation of new mineral deposits and existing operations

- Market assessments and feasibility studies

- Mining, processing, and marketing expertise to lower costs

- Business planning, operations management, and strategic planning

- Mergers and acquisitions due diligence

- Technical feasibility studies (i.e., lab, pilot, and applications testing)

- Identifying new high-value mineral products

- Strategies to meet customer needs at the lowest possible cost

Mineral Processing

EARTHRES uses a systematic approach to improve your mineral processing operation. We start with a thorough evaluation of your existing process, identify, and rank potential process improvements, conduct pilot tests, implement process changes, and measure the results. The end results are improved product quality, improved product yield, and increased profits.

EARTHRES’ systematic approach includes working with the client to complete a thorough evaluation of your process.

Thorough Process Evaluation

- Complete Mass Balance Development

- Process Flow Measurements, Unit Analysis, and Performance Evaluation of Equipment (i.e., Crushers, Screens, Cyclones, Dryers, Classifiers, Mills, Flotation Cells, Calciners, Magnets, Feeders, and Conveyors)

- Process Flow Sheet Development

- Prioritize Projects Based on Return On Investment (ROI)

- Project Management and Implementation of Identified Process Improvements

Plant Design

New Plant Design

- Evaluate the Deposit

- Based on the Deposit Evaluation, Design the Process to Optimize the Desired Product Mix and Maximize Production

Existing Plant Improvement

- Evaluate the Deposit

- Conduct a Thorough Evaluation of the Existing Process to Identify Opportunities for Improvement

- Implement the Identified Process Improvements to Optimize the Desired Product Mix and Maximize Production

Plant Optimization

Implement identified process improvements, in order of ROI, and measure the results of each process improvement with regard to product quality, product yield, and profitability.

Beneficial Reuse

Beneficial Reuse. Waste Minimization. Profits.

EARTHRES helps clients minimize waste in aggregate, industrial mineral, coal, and power plant operations through process improvement and beneficial reuse. Through beneficial reuse, we help the client manage costs and operate within increasingly stringent government relations. Globally, the cost of disposal, ongoing storage, and the liability of storing these materials represent a significant challenge for mining operations. Through proper materials characterization, process technology assessments, process improvements, and our market knowledge of functional additives and fillers, EARTHRES helps provide clients with creative strategies that can qualify mineral reserves or plant by-product streams for use in multiple end-use applications, minimize waste and reduce material storage costs and liabilities.

Initial Consultation

As part of our Engineering for SuccessSM platform, EARTHRES provides an initial consultation to evaluate the potential of your waste materials for waste minimization and/or beneficial reuse.

Characterization and Preliminary Market Evaluation

Following an on-site evaluation, EARTHRES can characterize the material and develop a preliminary assessment of processing strategies and applications for the material in the marketplace. EARTHRES then provides lab data that characterizes the material, processing strategies (if required) and recommendations for target markets for the material.

Market Development, Plant Design and Processing Cost Estimate

EARTHRES can perform pilot production studies, develop the product and specifications, present to specific customers in the client’s target market, and deliver a conceptual flow-sheet design and an operating cost estimate for production of the product. From conception to design, we have made improvements to existing facilities to either minimize the production of a waste product or identify a use for the waste material.