The Project: Shale Gas Well Pad Standardization

📍Marcellus-Utica Region

The Challenge

With the fast pace of construction in the shale gas development industry, well pad designs and equipment installations have varied significantly from site to site based on local conditions, well pad geometry, individual designers and contractors and equipment availability. EARTHRES was contracted by a developer to help standardize its equipment installations by analyzing several completed installations and developing 3D equipment design and construction. This would include preparing standardized as-built 3-D drawings of the preferred equipment arrangements to facilitate the installation at other sites to keep up with the fast pace of construction.

The Solution

3D Survey and Design

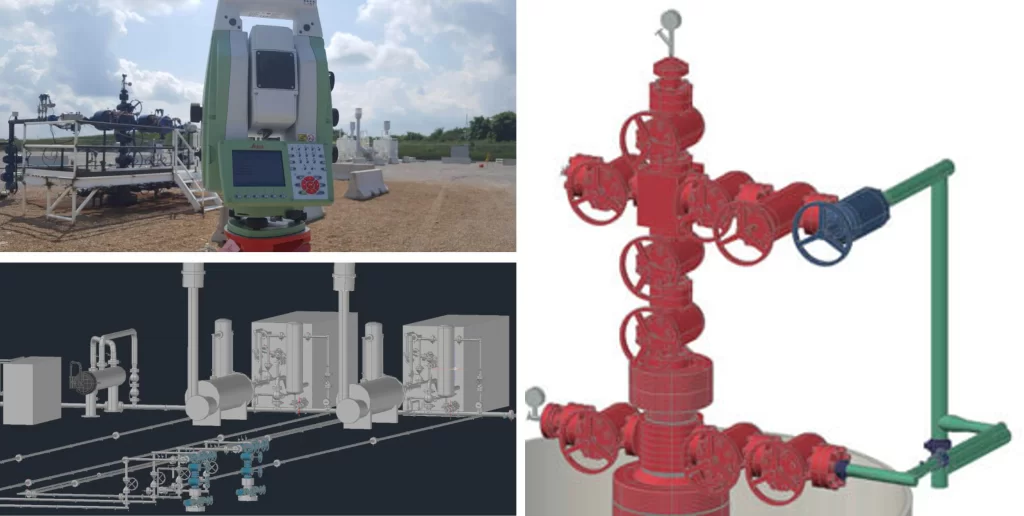

To develop a shale gas wellpad standardization, the EARTHRES engineering team gathered detailed as-built information on several owner-selected, completed wet natural gas production wellpad installations. EARTHRES used the collected data to create 3D design layouts of the client’s pad sites. Each unit operation layout prepared by EARTHRES consisted of 3-D construction drawings showing the equipment, piping, valves, and fittings. A complete Bill of Materials (BOM) was included in each drawing set. Unit operation designs were prepared for well-heads, sand traps, gas production units, heater-treaters, water and oil storage tanks, vapor recovery towers, compressors, as well as main gas collection headers that ultimately are connected to gathering lines and midstream conveyance infrastructure.

In addition to the unit 3D drawings, construction level plan view drawings showing gas production equipment locations and piping arrangement were developed by EARTHRES for newly-constructed, gas production wellpads. Each design was developed to minimize construction costs by optimizing piping lengths while maintaining adequate industry-standard offset and spacing distances. In addition, EARTHRES considered ease of expandability to accommodate the potential addition of future wells on each pad.

The construction-level drawings were incorporated into bid documents prepared by EARTHRES on a pad-specific basis. The bid documents included project construction schedules, expectations, payment terms, plan view design drawing(s), and applicable 3D standard unit installation drawings. EARTHRES managed the issuance and receipt of bid documents entirely in electronic format to reduce costs and increase efficiency in bidding the projects.

Data Archival

Once construction is complete, EARTHRES then conducts as-built surveys using reflectorless total station equipment for efficient data collection. State-of-the-art reflectorless surveying with digital imaging technology was used to gather the data. This technology allows for one person to conduct precise 3D data collection of equipment, piping and other constructed features even in elevated and congested locations. EARTHRES then prepares as-built drawings to document new site installations for inventory, archival and future planning.

The Results

This gas well pad equipment standardization will reduce variability in construction and result in a reduction of change orders and costs by improving contractor efficiency. Another anticipated benefit is improved efficiency in system maintenance and operation.